Email:info@abrasives-depot.com|Contact:+86-13179615576| Chinese

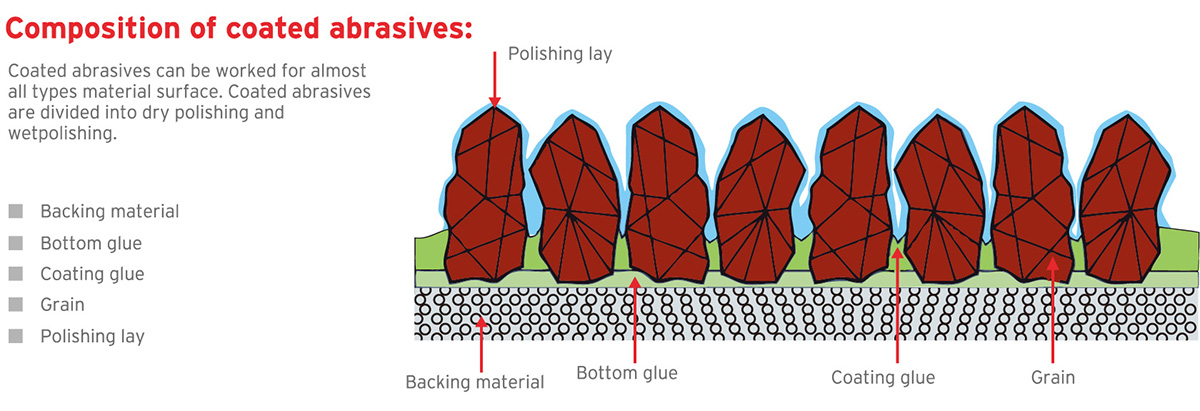

☑ Backing material

Bonder and grain are fixed on backing material. The selection of backing material varies depending on tensile strength, flexibility, and wear-resisting. Backing material selection should take requirement of polishing into consideration.

◆ Paper:

Paper backing material are usually used for wood processing industry and paint processing, a small scale in metal processing.

The abrasive products of manual polishing usually consist of 70-100g/M2 grain and paper backing material.

Heavy paper is used for manufacturing narrow sanding belt and wide sanding belt for stationary machine.

◆ Cloth:

Cloth backing coated abrasives mainly used for metal processing industry.

◆ Vulcanized fibre paper:

Different intensity vulcanized fibre paper mainly for producing different fiber abrasives discs.

Hard paper is very strong, hard, and wear-resisting.

◆ Bond:

It needs different resin bond to combine abrasive grain with backing material in manufacturing coated abrasives.

- Firstly spray bottom glue on backing material,

- then spray abrasive grain on the surface, and take special technique to adjust.

- Then the abrasive grain and bond combine well.

Bond supports abrasive grain well to bear external force and load in the processing.

◆ Abrasives grain:

The right choice of products is very important for economic value of surface processing and technology.

☑ Aluminium oxide:

Aluminum oxide is used for producing grain. It can change the hardness and toughness by bond and special manufacture method.

☑ Silicon carbide:

Silicon carbide is a kind of compositely produced abrasive grain. It is very sharp, low toughness, but with high hardness.

Silicon material is used for titanium, aluminum, copper, stone and plastic working.

☑ Zirconium:

Zirconium is smelting mixture of aluminum oxide and zirconium oxide.

Zirconium is softer but with more toughness compared with aluminum oxide.

High proportion aluminum oxide endows zirconium excellent self-sharpness.

☑ Ceramic grain:

The advanced grain toughness and self-sharpness are favored by various processing industry.

◆ Classification of grain grit:

There are provisions of different coated abrasive grain grit in ISO6344, and meanwhile apply to FEPA standard.

Rough : PSO 一 60 一 50 · 40 一 36 一 24 · 16

MedlUm : P 280 · 240 · 220 · 180 · 150 · 120 · 100

Fine : P 600 · 500 · 400 , 360 · 320

EXtra fine : P 1500 · 1200 · 1000 · 800