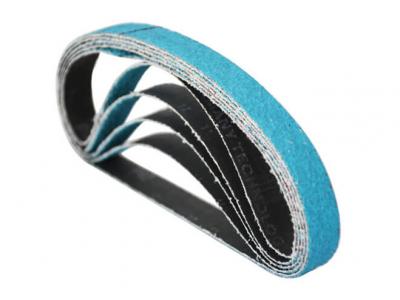

For Grinding Polishing Metal/Woods, cast iron, stainless steel, carbon steel , hardwood board heavy duty grinding work

◀ Material:Zirconium oxide

◀ Backing:Polyester Cloth

◀ Abrasive cloth:Y-wt heavy duty polyester cloth

◀ Size:Width 10-120mm , length 330-9000mm

◀ Grit:36 - 400#

◀ Cloth Grade:Very sturdy or rigid

- Zirconia alumina belts are the go to choice for aggressive sanding, grinding of metals and hardwoods.

- These belts are built on a robust X-weight polyester abrasive cloth backing. they are intended for wet or dry use.

- These belts can be used on back-stand belt grinders, knife belt sanders, benchstand grinders, portable belt sanders and a wide assortment of home built grinders.

- Mainly apply in a variety of metals like steel, stainless steel, carbon steel, aluminum, etc.

FEATURES

◀ Flexible cloth backing provides ideal comfortable for blending and finishing contours and complex parts

◀ Lighter weight backing is ideal for medium to fine grades and reduces cost

◀ Superior durability and cut-rate with consistent performance

◀ Longer life than comparable aluminum oxide belts

◀ lower cost per part and less time lost to belt changeovers

It can be customized by customer's requirements. It has different sizes to choose from and has a high tensile strength and great tension.

APPLICATION

◀ Grinding of hard heat steel, hard wood board

◀ zirconia alumina abrasive belt suitable for heavy grinding and polishing with middle or heavy load, for steel, alloy-steel, cast iron and nonferrous metal.

ADVANTAGE

◀ Flexible cloth backing, lighter weight backing is ideal for medium to fine grades and reduces cost.

◀ Precision Shaped Grain provides superior durability and cut-rate, with consistent performance, which translates to higher production rates. longer life than comparable aluminum oxide belts,

◀ Which means a lower cost per part and less time to change belt

STORAGE INSTRUCTION

◀ Temperature and humidity requirements:

-The ideal temperature is: 18-220C;

-The ideal humidity is 40-65%

The abrasive belt should not be stored in a place where the temperature and humidity change greatly.

◀ If the temperature is too high, the binder will age and reduce the service life of the belt.

◀ Synthetic fiber matrix belts (such as polyester cloth belts) are sensitive to cold and cannot be stored in cold warehouses.

SAFETY INSTRUCTION

◀ Always wear the appropriate protective equipment when using these belts.

◀ If the humidity is too high or too low, the belt will be deformed, and the deformation will reduce the bond strength of the belt sand layer.

◀ Excessive humidity has a serious impact on the abrasive belt.

◀ In addition to water-resistant abrasive belts, the general belts are used after being damped, and they are prone to discounts and wrinkles, which cause the belt machine to be scrapped.

◀ In addition, the abrasive material is easily adhered to the surface of the abrasive belt when the wet abrasive belt is ground, reducing the service life of the abrasive belt.

◀ The high temperature and low humidity have a great influence on the paper-based abrasive belt, which makes the paper-based abrasive belt brittle and easy to break and scrap when used.