Non-woven Flap Grinding Machine Polishing Wheels, Radiant Pads Nylon Stainless Steel, Non Woven Abrasives Wheel

Many factors of non-woven abrasive are in the radioactive arrangement, each layer combs into line and be compacted, ensure long working life.

◀ Material: Aluminum Oxide/Silicon Carbide

◀ Color: Green/Maroon

◀ Size: Regular & can be customized

◀ Hole Shape: Cross/Arbor hole

◀ Grits:60 - 3000#

FEATURES

◀ Waterproof and Flexible,

◀ non-woven abrasives are unique surface conditioning products with abrasives incorporated into non-woven fiber matrix.

◀ Combining abrasives and non-woven material creates an abrasive system that delivers consistent results for the life of the product.

◀ The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.

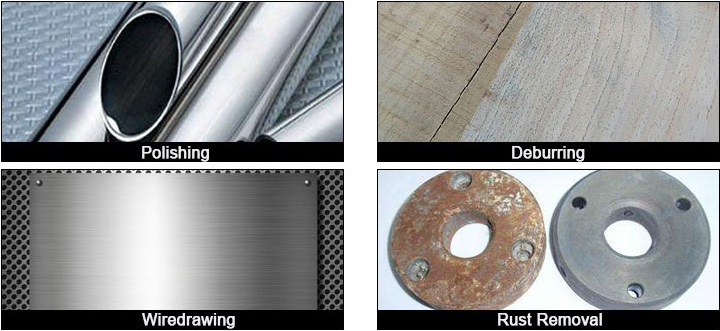

APPLICATION

◀ For drawing, Satin and Finishing of wooden, Stainless Steel and Metal Products.

◀ It is made of high temperature nylon fiber, superior abrasive, imported resin and polishing fiber,

◀ This is endowed with good finishing capability, excellent polishing ability and fine durability.

PRODUCT PARAMETERS

Production | Size | Grit | Color |

Non woven wire drawing wheel | 120*100*19mm | 60/80/120/180 | Maroon |

115*100*19mm | |||

110*100*19mm | |||

100*100*19mm | |||

8698 wire drawing wheel | 120*100*19mm | 240 | Green |

115*100*19mm | |||

110*100*19mm | |||

100*100*19mm | |||

7447 wire drawing wheel | 120*100*19mm | 320 | Maroon |

ADVANTAGE

◀ Cool grinding

◀ Different sizes, grits and models

◀ Highly open, no blocking

◀ Flexibility and open effect of non-woven makes it has fine elasticity and cool grinding ability.

◀ Make no change to the geometric profile of work-piece surface because of the flexibility. Achieve different coarse and fine degrees of surface.

SAFETY INSTRUCTION

◀ Pick the right speed to produce the best results

◀ When the product is used at the perfect operating speed of 19m/s, the generated centrifugal force causes the flaps to stand upright.

◀ They will only bend to a negligible degree even under a higher tool pressure.

◀ Achieving the perfect result hinges on the optimum ratio between the speed of the satin finishing machine and the diameter of the satin finishing drum.

◀ With fixed speed, a suitable mop wheel size can be selected, which is produced by JKX in different diameters. For variable speed machine, the speed can be adjusted to suit the drum diameter.