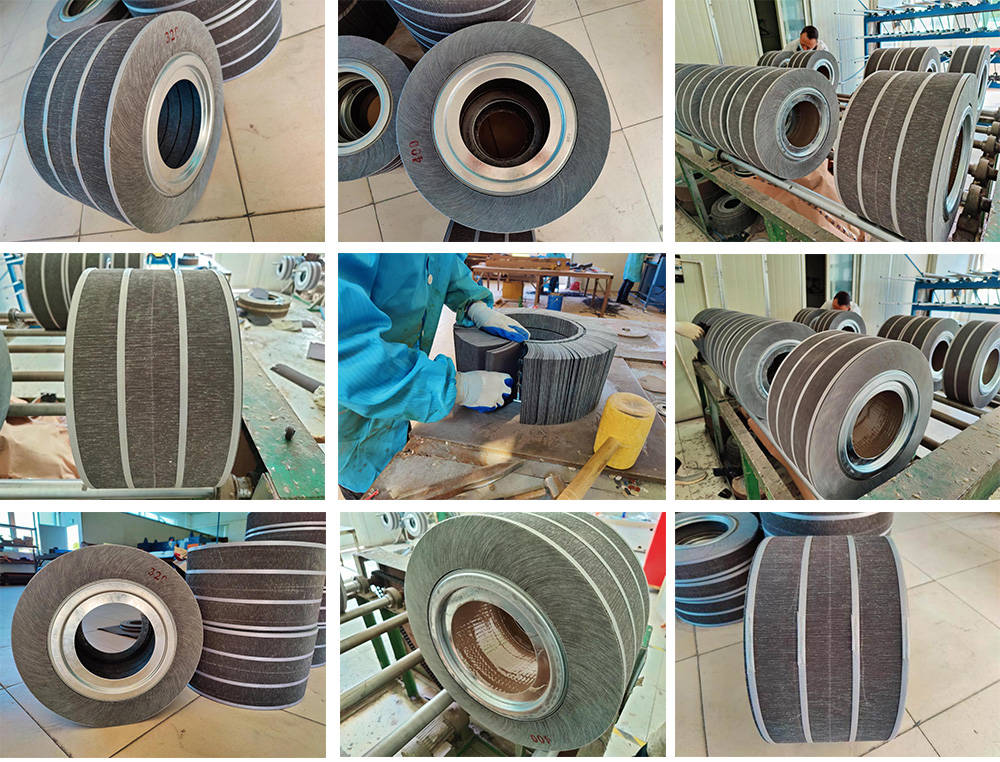

◀ Material: Aluminum Oxide, Silicon Carbide, Calcined Alumina, Zirconia, Ceramics

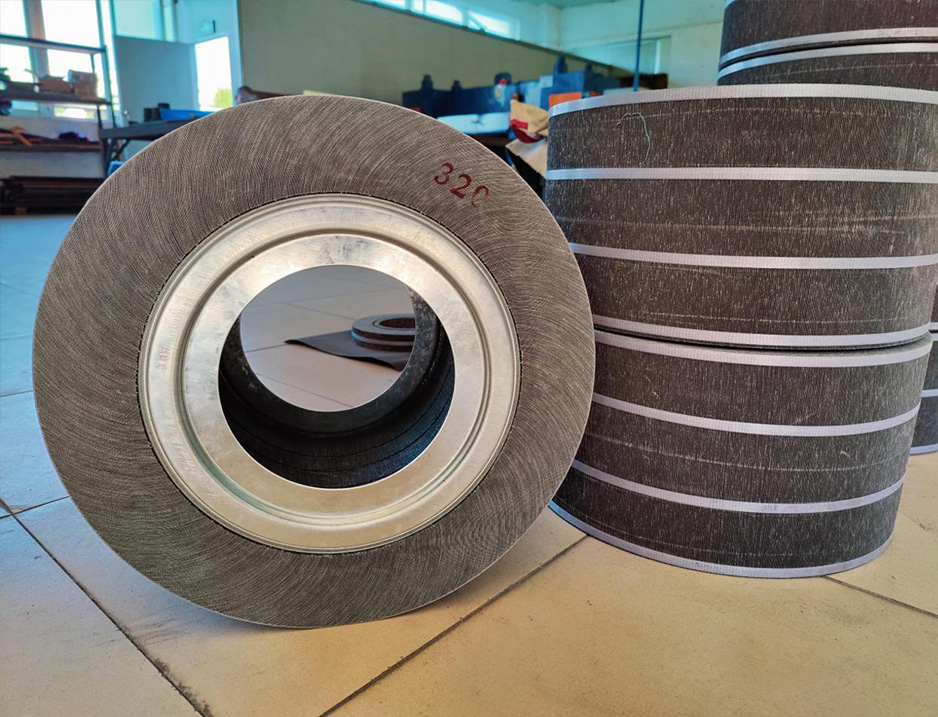

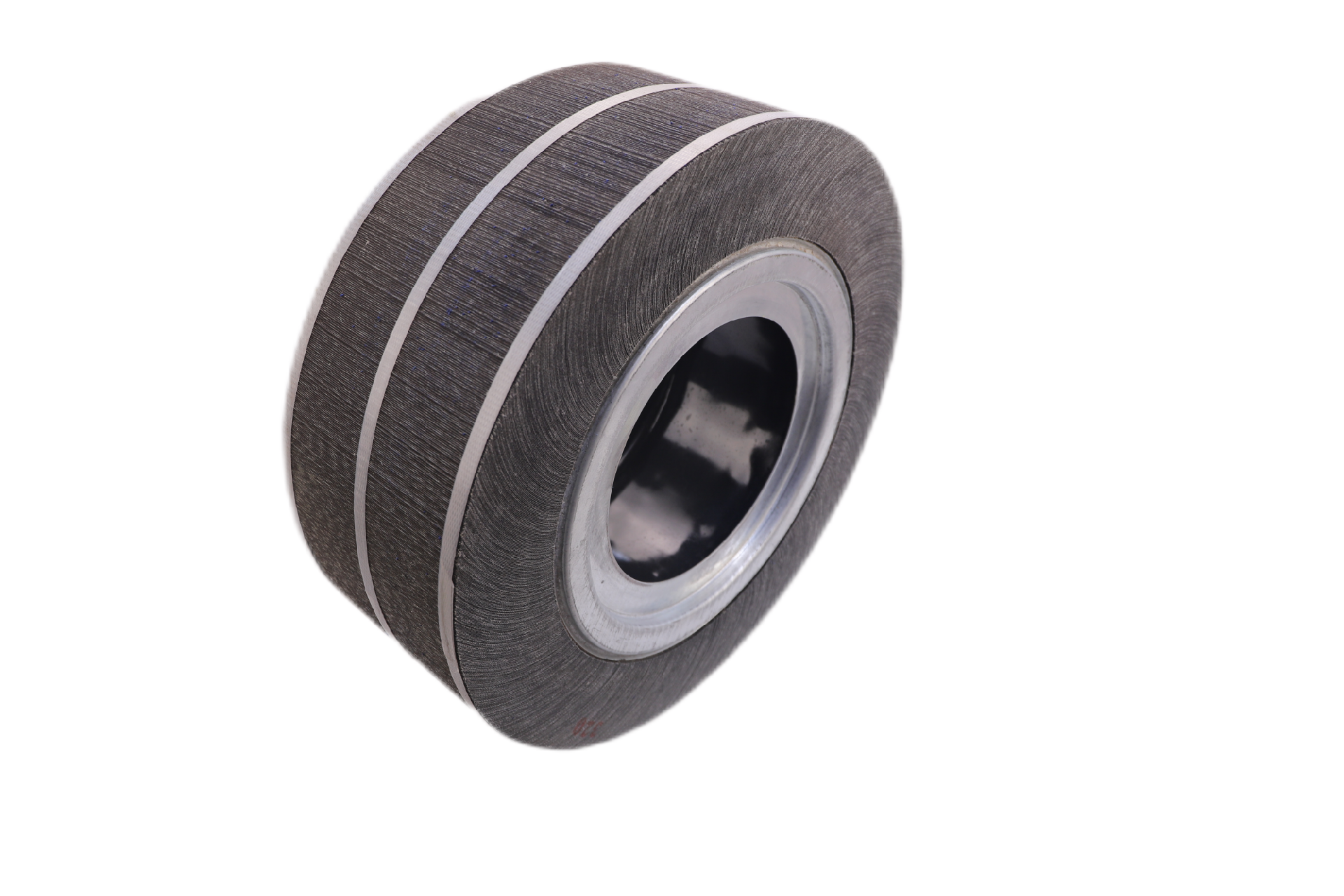

◀ Outside Diameter:100/150/ 200/ 250/ 300/ 350/400/ 450 mm & customization

◀ Thickness: 10/ 12/ 15/ 20/ 25/ 30/ 40/ 45/ 50/ 60/ 65/ 75/ 80/ 95/ 100/ 120 mm & customization

◀ Bore Size:16/ 25.4/32/ 36/38.1/ 127/ 185 mm & customization

◀ Grits:24#/40#/ 60#/ 80#/ 100#/ 120#/150#/180#/ 240#/ 320#/ 400#/ 600#/ 800#/ 1000#/ 1200# & customization

FEATURES

◀ High-quality abrasive sandpaper & cloth

◀ High working efficiency stable grinding quality

◀ No burning work-pieces

◀ Easily continuous operating.

APPLICATION

◀ Metal, non-ferrous metal surface grinding and polishing, weld seams grinding, rust removing

ADVANTAGE

◀ Flap wheels are conformable to intricate shapes and contours, high working efficiency, stable grinding quality, no burning working pieces, easily continuous operating.

◀ Design to deliver a consistent finish with a uniform rate of cut, flap wheels wear away, continually exposing fresh abrasive.

◀ Silicon Carbide abrasive cloth substrate keep synchronous consumption. Good heat dissipation, do not burn work-piece.

◀ for a wide variety of blending, deburring and finishing applications common in the metal fabrication, welding and polishing wood industries.

Good brightness after grinding can be used as one-time grinding, no need last procedure of polishing

SAFETY INSTRUCTION

◀ The protective cover is the main protective device of the polishing machine, when the flap wheel is damaged in the work, can effectively cover the impeller, to ensure the safety of personnel.

◀ The balance of the flap wheel is mainly caused by the manufacture and installation of hundreds of flaps of inaccurate so that the center of gravity and rotary shaft do not coincide. The harm caused by the imbalance is mainly shown in two aspects, on the one hand, in the high-speed rotation of the vane wheel, cause vibration, easy to cause the workpiece surface polyangular vibration marks, on the other hand, the unbalanced acceleration of the spindle vibration and bearing wear, serious will cause the vane wheel page rupture, even cause accidents.

◀ The matching problem mainly refers to the installation problem of chuck and flaps. According to the standard requirements, the diameter of the chuck shall not be less than 1/3 of the diameter of the installed sand disc, and the corresponding provisions wear to the diameter larger than the chuck 10mm should be replaced with a new flap wheel.