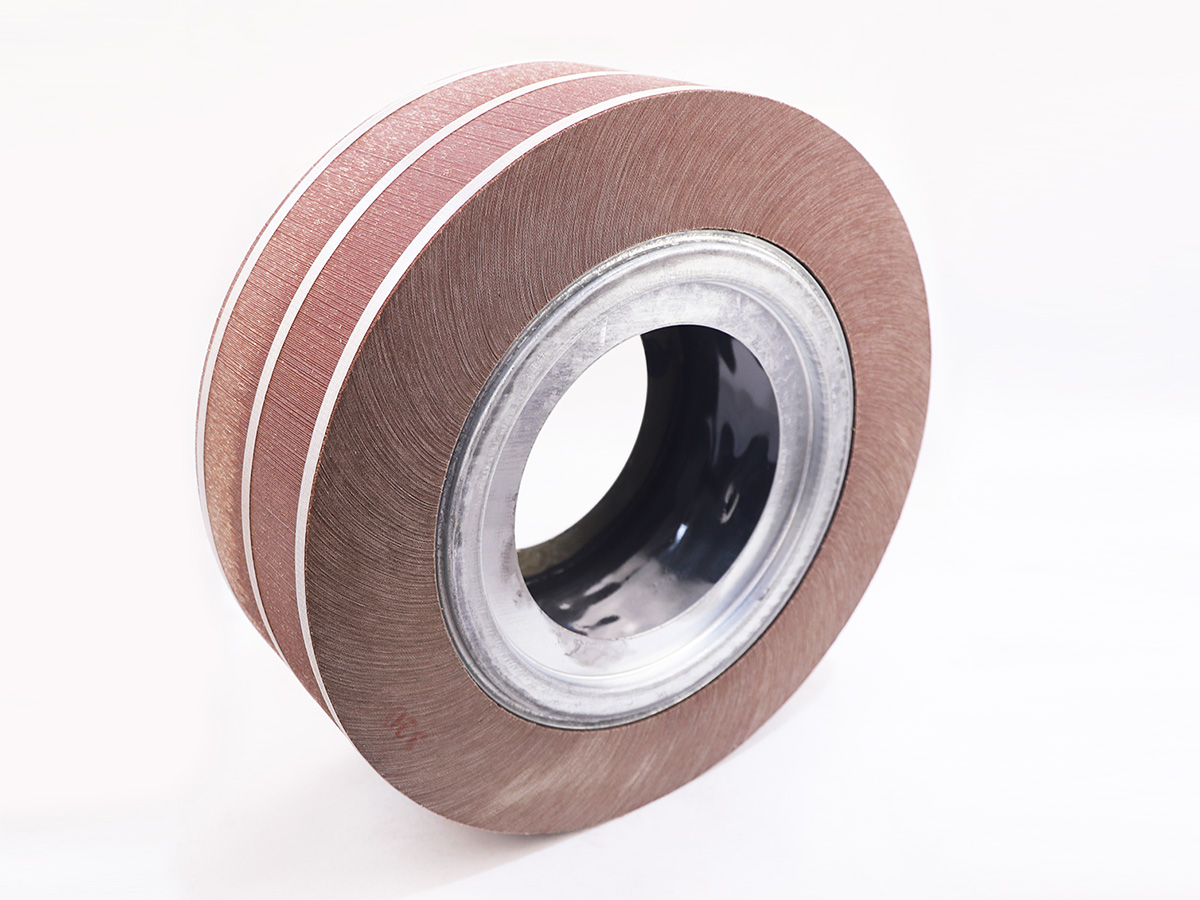

Abrasive Disc Aluminium Oxide Bench Grinding Wheel for General Purpose

Mainly install on electric tool or polishing machine for wooden ,stainless steel ,metal grinding ,polishing,rust removing

◀ Material: Aluminum Oxide

◀ Outside Diameter:100/150/ 200/ 250/ 300/ 350/400/ 450 mm

◀ Thickness: 10/ 12/ 15/ 20/ 25/ 30/ 40/ 45/ 50/ 60/ 65/ 75/ 80/ 95/ 100/ 120 mm

◀ Board Size:16/ 25.4/32/ 36/38.1/ 127/ 181 mm

◀ Grits:24/40/ 60/ 80/ 100/ 120/150/180/ 240/ 320/ 400/ 600/ 800/ 1000/ 1200 mm

FEATURES

◀ Flaps made from poly cotton cloth keep the wheel durable,

◀ Wear resistant, and conformable.

◀ Consistent and fine polishing surface.

APPLICATION

◀ Finishing wide, flat, concave and convex surface,

◀ grinding the internal and outer surface of tanks, containers and pipes, finishing parts of irregular shape such as handles, taps and molded parts.

◀ Removing and cleaning welding seams.

◀ for a wide variety of blending, deburring and finishing applications common in the metal fabrication, welding and polishing industries.

PRODUCT PARAMETERS

Specification | Abrasive grain | Grit No. | ||

Diam.(mm) | Height(mm) | Thickness(mm) |

|

|

150 | 25 | 25/32 | Aluminum oxide | 40#-1200# |

200 | 25 | 25/32 | Aluminum oxide | 40#-1200# |

30 | ||||

40 | ||||

50 | ||||

250 | 30 | 25/32/50 | Aluminum oxide | 40#-1200# |

40 | ||||

50 | ||||

300 | 25 | 25/32/50127 | Aluminum oxide | 40#-1200# |

30 | ||||

40 | ||||

50 | ||||

60 | ||||

70 | ||||

80 | ||||

90 | ||||

100 | ||||

350 | 60 | 145 | Aluminum oxide | 40#-1200# |

70 | ||||

80 | ||||

90 | ||||

100 | ||||

Note: Customization is welcome to meet your request. | ||||

ADVANTAGE

◀ This product can be applied to most irregular surfaces and both inner and outer wall of your product.Such as stainless steel utensils,pots,bowls,ladles etc..

◀ It is also commonly used in automobile manufacture,heavy machinery,ship repair,aluminum alloy,hardware and decoration industries.

◀ Suitable for rough polishing,repairing,derusting and grinding of various irregular surfaces with high polishing efficiency and long service life.

◀ It can absolutely match to the workpieces,and it provides a smooth abrasion on the workpieces’s surface during it’s lifetime.

◀ It has the characteristics of good elasticity,stable physicochemical property,high security,and safe not to burn the workpieces.

SAFETY INSTRUCTION

◀ The protective cover is the main protective device of the polishing machine, when the flap wheel is damaged in the work, can effectively cover the impeller, to ensure the safety of personnel.

◀ The balance of the flap wheel is mainly caused by the manufacture and installation of hundreds of flaps of inaccurate, so that the center of gravity and rotary shaft do not coincide.The harm caused by the imbalance is mainly shown in two aspects, on the one hand, in the high speed rotation of the vane wheel, cause vibration, easy to cause the workpiece surface polyangular vibration marks, on the other hand, the unbalanced acceleration of the spindle vibration and bearing wear, serious will cause the vane wheel page rupture, even cause accidents.

◀ The matching problem mainly refers to the installation problem of chuck and flaps. According to the standard requirements, the diameter of the chuck shall not be less than 1/3 of the diameter of the installed sand disc, and the corresponding provisions wear to the diameter larger than the chuck 10mm should be replaced with a new flap wheel.